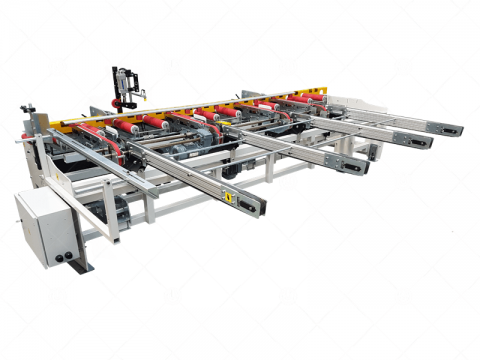

- Automated equipment, which was developed for the outfeed of pieces / profiles along continuous production lines such as painting and extrusion lines (plaster), coating/lamination lines and others.

- Its automation allows it to operate continuously and can reach up to 5 cycles/ minute.

This equipment had its constructive format elaborated in such a way, which allows the operational assembly in two different directions, thus meeting all the existing conditions in the market in terms of layout. - Its principle of operation consists in discharging a layer of parts/profiles or panels.

VACUUM AUTOMATIC OUTFEED BY ELEVATION FF 1007 DAVE

Technical Description

Equipment Sizing:

– Length: 7000 mm.

– Width: 3100 mm.

– Height: 3200 mm.

Sizing Parts/Profiles:

– Length: 6096 mm.

– Width: 1000 mm.

– Height: 80 mm.

RELATED EQUIPMENT