- Automated equipment, developed for the application of Stretch film in the sub-packages (bundle), providing automation for the packaging line.

- This equipment is intended for assembly at the end of the continuous production line, such as painting and extrusion (gesso) lines, coating lines, among others.

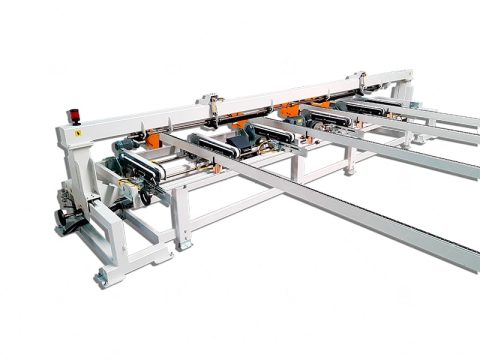

- This equipment had its constructive format elaborated in such a way, that it allows the operational assembly in two different directions, thus meeting all the existing conditions in the market in terms of layout.

- Its working principle consists of receiving a subpackage of pieces/profiles (stacked) in the transverse direction, being automatically transferred to the stretch application area, where the applicator heads are raised and apply the stretch in a rotating way, involving the subpackages. After the stretch is cut, the heads are recessed and then the subpack is moved out of the equipment, all automatically.

- The MOTORING STRETCH MOBILE APPLICATOR WITH RAILS FOR BETA FF 304 AMSATPB PROFILES, allows you to operate with pieces/profiles up to 300 mm wide and has 4 applicator heads, both adjustable.

- Modulated and large structure, built in carbon steel.

- Surface treatment (paint) being done with liquid EPOX.

MOORING STRETCH MOBILE APPLICATOR WITH RAILS FOR PROFILES BETA FF 304 AMSATPB

Technical Description

Dimensionamento do Equipamento:

– Comprimento: 1890 mm.

– Largura: 6036 mm.

– Altura: 1645 mm.

Dimensionamento de Peças e Perfis:

– Comprimento: 5486,4 mm.

– Largura: 200 mm.

– Altura: 200 mm.

Dimensionamento da Bobina de Embalagem:

– Diâmetro Externo: 180 mm.

– Diâmetro Interno: 76,2 mm.

– Largura: 70 mm.

RELATED EQUIPMENT