What to consider before buying your first industrial machine

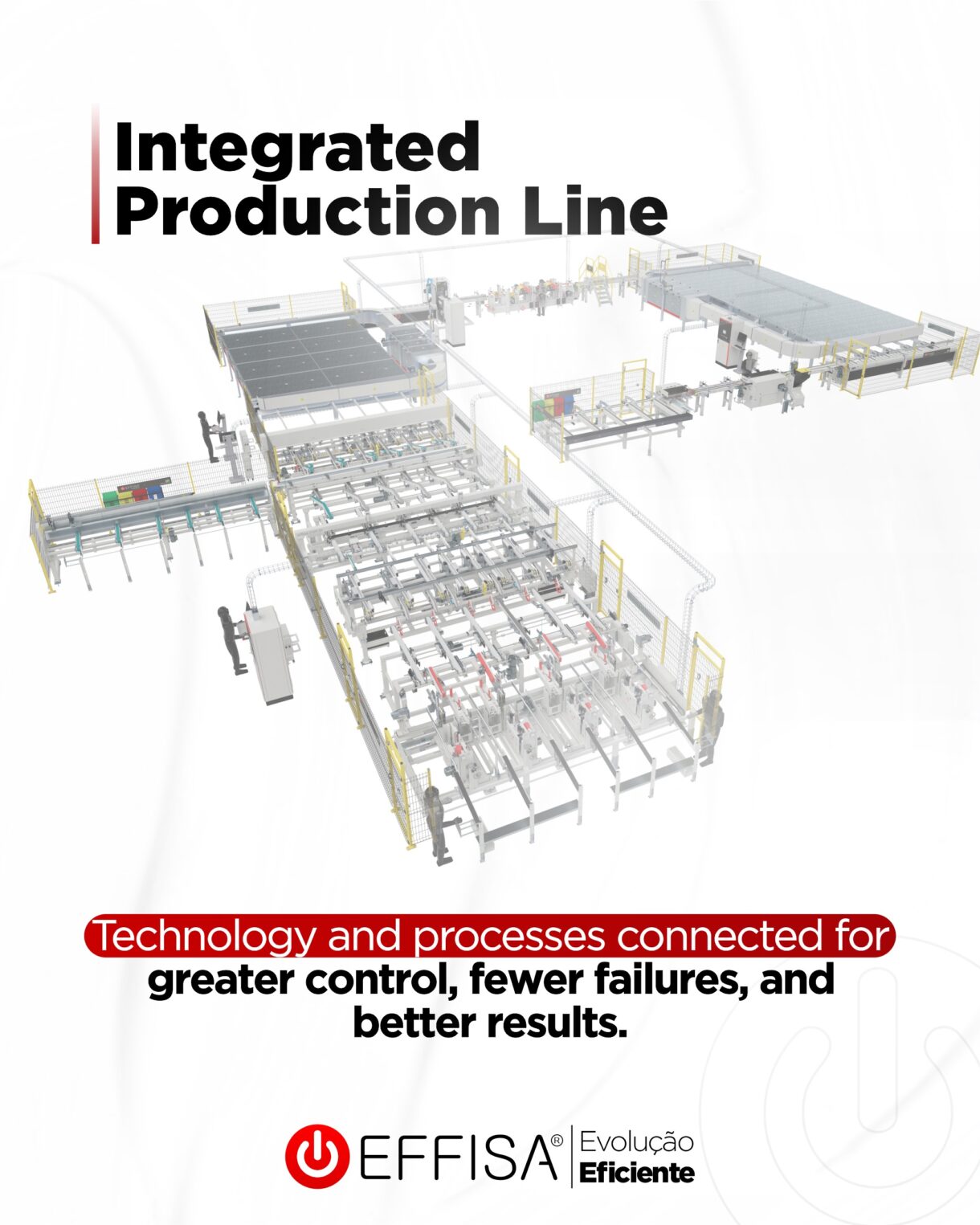

Before investing in your first industrial machine, it is essential to understand your production needs, workload volume, and available space. Evaluating production capacity, energy consumption, and operating costs helps avoid unnecessary expenses in the future.

It is also important to consider ease of operation, equipment safety, and compliance with technical standards. In addition, technical support, maintenance, and spare parts availability are crucial to prevent production downtime.

In this context, EFFISA has a specialized team that supports clients in gathering all the necessary information, including an analysis of current operating costs compared to the investment in new solutions. This study clearly defines the return on investment (ROI), providing greater accuracy and confidence in decision-making.

Based on this analysis, EFFISA guides clients in choosing the ideal solution, offering reliable equipment, specialized technical support, and after-sales service that supports business growth, ensuring continuous productivity and real return on investment.