- Equipment available in two different models:

Mod. FF 303 MALPO, used for linear feeding of profiles, approximate length of 3 m.

Mod. FF 306 MALPO, used for linear feeding of profiles, approximate length of 6 m.

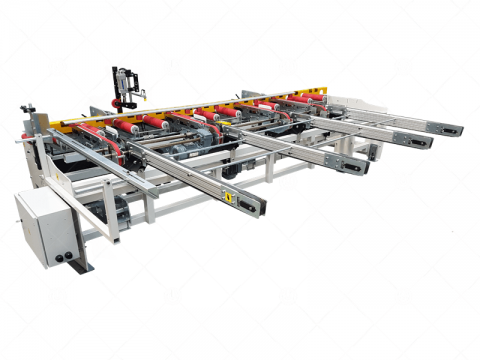

- In this particular image, we are presenting the model FF 306 MALPO.

- Automated equipment, which was developed to feed parts / profiles along continuous production lines such as painting and extrusion lines (gypsum), Sanding, wrapping lines and others.

- Its vertical storage concept enables it to operate continuously at high speeds and can reach 110 m / min in a linear direction.

- The Profile Linear Loader Table Omega FF 306 MALPO had its constructive format elaborated in such a way that it enables the operational assembly in two different directions, thus meeting all the existing conditions in the market in terms of layout.

- Its principle of operation consists of making the parts / profiles accumulate vertically, being continuously transferred with speed in the linear direction, giving the continuous feeding to a production line