- Automated equipment, which was developed for the off loading of parts / profiles along continuous production lines such as paint and extrusion lines (gypsum), sanding, wrapping lines and others.

- Its working principle is to do the off loading, whether or not followed by the division of the parts / profiles in a transverse way, giving an end to a production line.

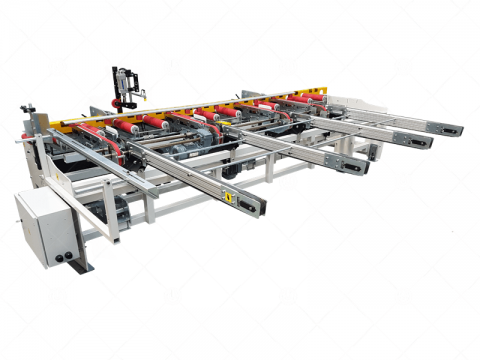

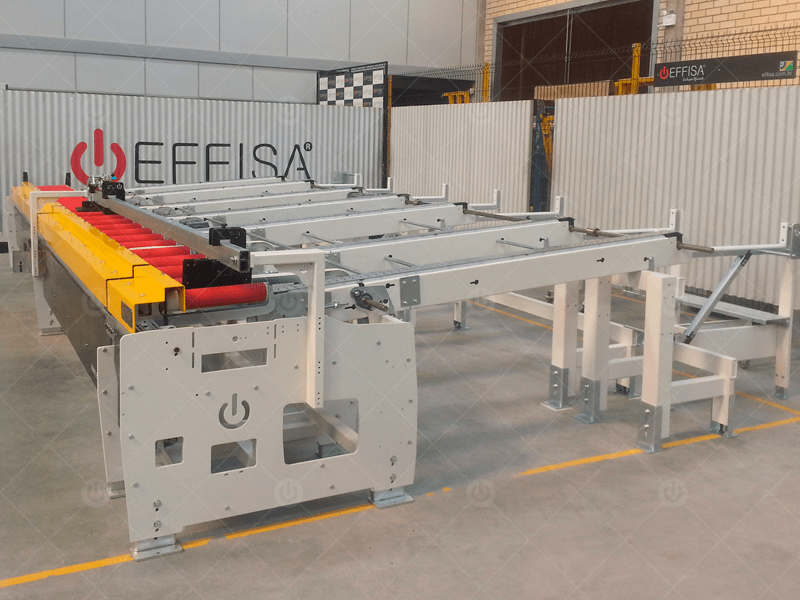

- The Profile Transversal Off-loader Table Beta FF 306 MDTPB operates with aligning rollers for profile orientation, working in conjunction with lower cutting heads, dividing them according to the need of the process.

PROFILE TRANSVERSAL OFF-LOADER TABLE BETA FF 306 MDTPB

Technical Description

Equipment Sizing:

– Length: 6200 mm.

– Width: 3935 mm.

– Height: 1150 mm.

Sizing Parts/Profiles:

– Length: 5800 mm.

– Width: 300 mm.

– Height: 80 mm.

RELATED EQUIPMENT